SPEEDMAT RAM

SPEEDMAT RAM

T-type boring and milling center with RAM

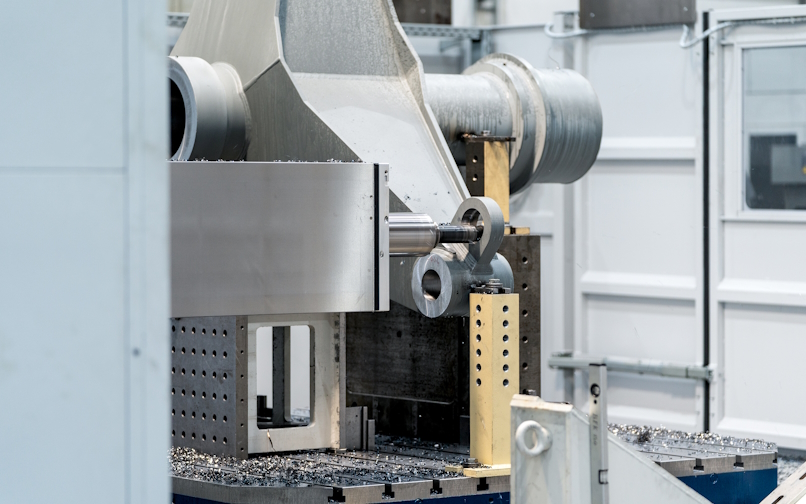

PAMA Speedmat RAM boring and milling centers are able to combine maximum rigidity and high precision to satisfy the most difficult applications when machining small- and medium-sized components.

PAMA Speedmat RAM boring and milling centers are distinguished by a T-type structure with a movable column and a travelling table. The column is thermal symmetric with a central headstock for maximum precision.

They are available in the milling version and in the milling and turning multitasking version.

The structures of the PAMA Speedmat RAM machine were studied using modern finite element state analysis techniques with the purpose of optimising the masses and guarantee high static and dynamic rigidity, as well as greater thermal symmetry.

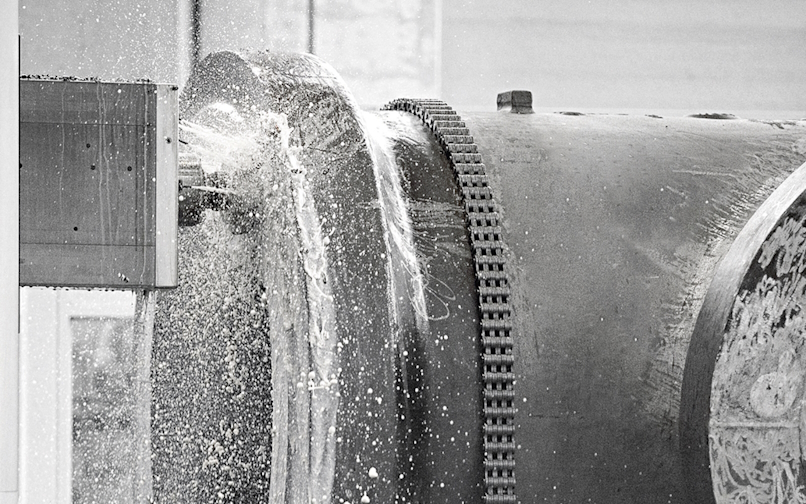

The focal point of the PAMA Speedmat RAM machine is the ram, guided inside the headstock by hydrostatic pads, which has a real-time feedback system to compensate for any elongation caused by temperature variations.

This solution guarantees maximum precision and rigidity together with high damping of the vibrations, at the location where they are generated.

To better satisfy customer requirements, the machine can be configured with one of the following headstocks:

- W headstock-ram equipped with a boring bar, with mechanical transmission

- WD headstock-ram equipped with a boring bar, with Direct Drive transmission

- MD headstock-ram equipped with a driver, with Direct Drive transmission

The boring bar (W and WD headstock) has a feedback system to compensate for any elongations caused by temperature variations; PAMA patent.

In line with PAMA’s tradition, the milling tables are equipped with hydrostatic rotating axes to guarantee maximum rigidity and maximum damping while machining.

To satisfy the growing request for multitasking machining, PAMA has developed and patented a series of hybrid tables, called TRT, which combine the advantages of rolling bearings with those of hydrostatic support.

The versatility of the PAMA Speedmat RAM machine can be increased with a wide range of CNC attachment heads, table pallet systems, as well as, automatic tool and attachment head changing systems.

From a software point of view, the machines can be configured by selecting from among CNC Siemens, Heidenhain and Fanuc.

TECHNICAL INFORMATION

SPEEDMAT RAM

| 3000 - 3800 - 4600 |

|---|

| WORKING AREA |  |  | ||||||

|---|---|---|---|---|---|---|---|---|

| X axis stroke (Table) | mm | 2200 - 5000 | ||||||

| Y axis stroke (Headstock) | mm | 1750 - 3750 | ||||||

| V axis stroke (Column) | mm | 1500 - 4000 | ||||||

| Z axis stroke (Ram) | mm | 1200 | ||||||

| Swing diameter | mm | 2200 - 4600 |

| MILLING TABLES |  |  | ||||||

|---|---|---|---|---|---|---|---|---|

| Table or pallet size | mm | 1250x1250 - 2000x3000 | ||||||

| Load capacity | kg | up to 25000 | ||||||

| B axis rapid feed | rpm | up to 5 |

| TURNING TABLES |  |  | ||||||

|---|---|---|---|---|---|---|---|---|

| Table or pallet size | mm | Ø1600 - Ø2500 | ||||||

| Load capacity | kg | up to 15000 | ||||||

| Turning speed | rpm | up to 250 |

| W HEADSTOCK-RAM (boring bar with range change) |  |  | ||||||

|---|---|---|---|---|---|---|---|---|

| ||||||||

| Ram section | mm | 430x430 | ||||||

| Boring spindle diameter | mm | 130 - 160 | ||||||

| W axis (boring spindle) | mm | 800 | ||||||

| Spindle transmission | 2 ranges | |||||||

| Spindle power (S1) | kW | 41 - 82 | ||||||

| Spindle torque (S1) | Nm | 1389 - 3451 | ||||||

| Spindle speed | rpm | 3000 - 4000 |

| WD HEADSTOCK-RAM (direct drive boring bar) |  |  | ||||||

|---|---|---|---|---|---|---|---|---|

| ||||||||

| Ram section | mm | 430x430 | ||||||

| Boring spindle diameter | mm | 120 | ||||||

| W axis (boring spindle) | mm | 600 | ||||||

| Spindle transmission | Direct Drive | |||||||

| Spindle power (S1) | kW | 66 | ||||||

| Spindle torque (S1) | Nm | 1175 | ||||||

| Spindle speed | rpm | 5000 |

| MD HEADSTOCK-RAM (direct drive driver) |  |  | ||||||

|---|---|---|---|---|---|---|---|---|

| ||||||||

| Ram section | mm | 430x430 | ||||||

| Spindle transmission | Direct Drive | |||||||

| Spindle power (S1) | kW | 66 - 90 | ||||||

| Spindle torque (S1) | Nm | 822 - 1175 | ||||||

| Spindle speed | rpm | 6000 |

| LINEAR AXES FEATURES |  |  | ||||||

|---|---|---|---|---|---|---|---|---|

| X,Y,V,Z axes rapid feed | mm/min | up to 40000 |

CONTACT

We are always at the disposal of our customers and future customers. Fill in the form with the required information and you will be contacted by the relevant department.